Manipulation and sensing have long been considered two key pillars for unlocking robotics’ potential. There’s a fair bit of overlap between the two, of course. As grippers have become a fundamental element of industrial robotics, these systems require the proper mechanisms for interacting with the world around them.

Vision has long been a key to all of this, but companies are increasingly looking to tacticity as a method for gathering data. Among other things, it gives the robot a better sense of how much pressure to apply to a given object, be it a piece of produce or a human being.

A couple of months back, Edinburgh, Scotland-based startup Touchlab won the pitch-off at our TC Sessions: Robotics event, among some stiff competition. The judges agreed that the company’s approach to the creation of robotic skin is an important one that can help unlock fuller potential for sensing. The XPrize has thus far agreed, as well. The company is currently a finalist for the $10 million XPrize Avatar Competition.

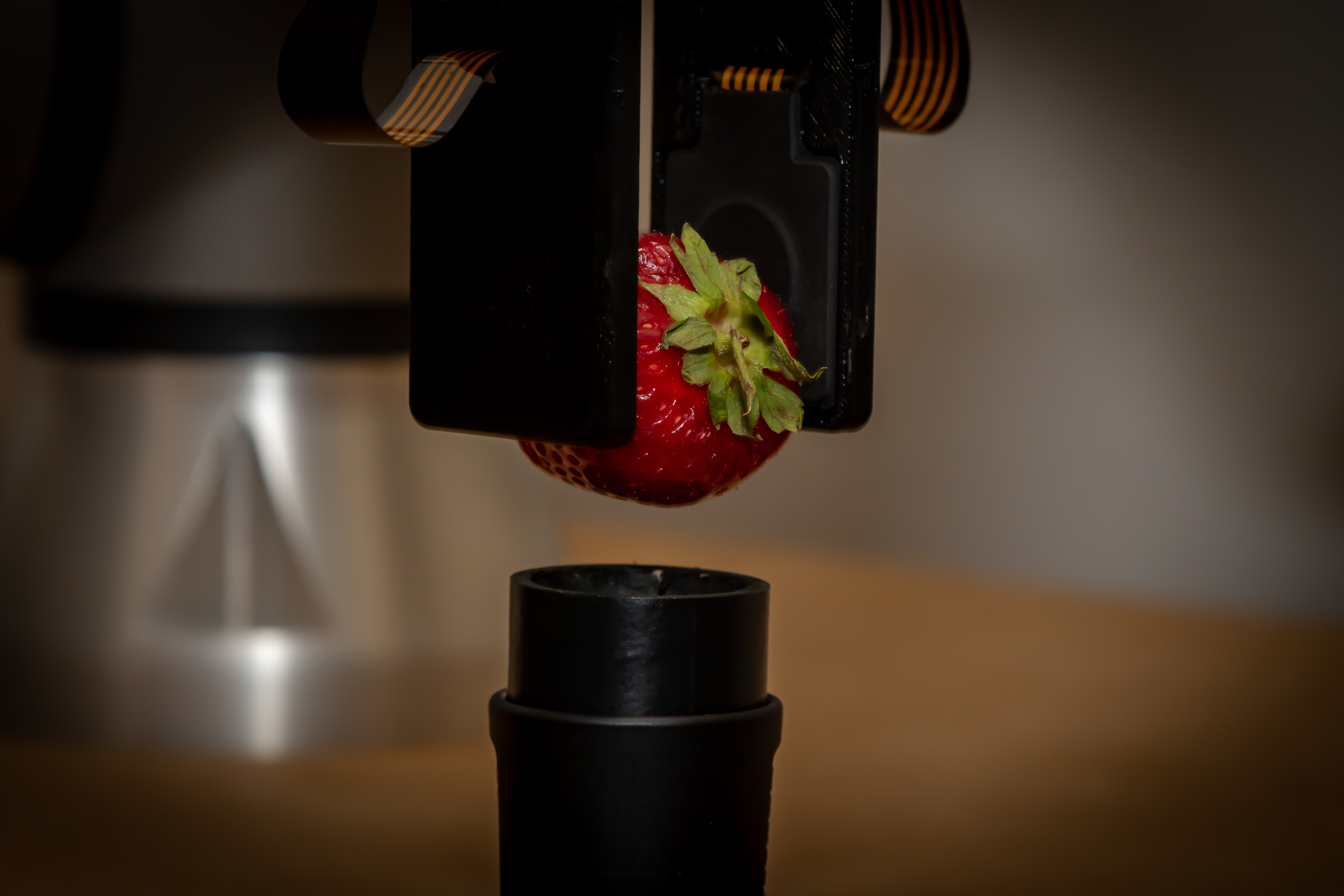

The firm is currently working with German robotics firm Schunk, which is providing the gripper for the XPrize finals.

Image Credits: Touchlab

“Our mission is to make this electronic skin for robots to give machines the power of human touch,” co-founder and CEO Zaki Hussein said, speaking to TechCrunch from the company’s new office space. “There are a lot of elements going into replicating human touch. We manufacture this sensing technology. It’s thinner than human skin and it can give you the position and pressure wherever you put it on the robot. And it will also give you 3D forces at the point of contact, which allows robots to be able to do dexterous and challenging activities.”

To start, the company is looking into teleoperation applications (hence the whole XPrize Avatar thing) — specifically, using the system to remotely operate robots in understaffed hospitals. On one end, a TIAGo++ robot outfitted with its sensors lends human workers a pair of extra hands; on the other, an operator outfitted with a haptic VR bodysuit that translates all of the touch data. Though such technologies currently have their limitations.

Image Credits: Touchlab

“We have a layer of software that translates the pressure of the skin to the suit. We’re also using haptic gloves,” says Hussein. “Currently, our skin gathers a lot more data than we can currently transmit to the user over haptic interfaces. So there’s a little bit of a bottleneck. We can use the full potential of the best haptic interface of the day, but there is a point where the robot is feeling more than the user is able to.”

Additional information gathered by the robot is translated through a variety of different channels, such as visual data via a VR headset. The company is close to beginning real-world pilots with the system. “It will be in February,” says Hussein. “We’ve got a three-month hospital trial with the geriatric patients in the geriatric acute ward. This is a world-first, where this robot will be deployed in that setting.”